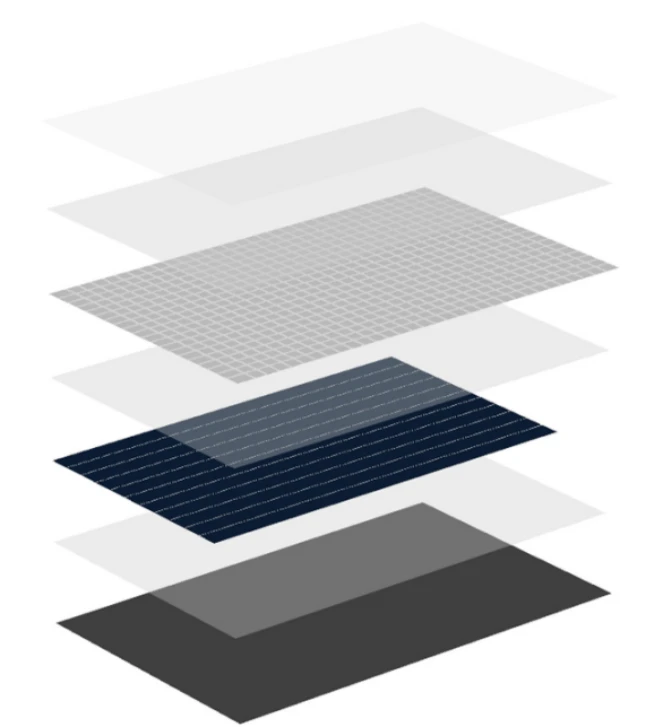

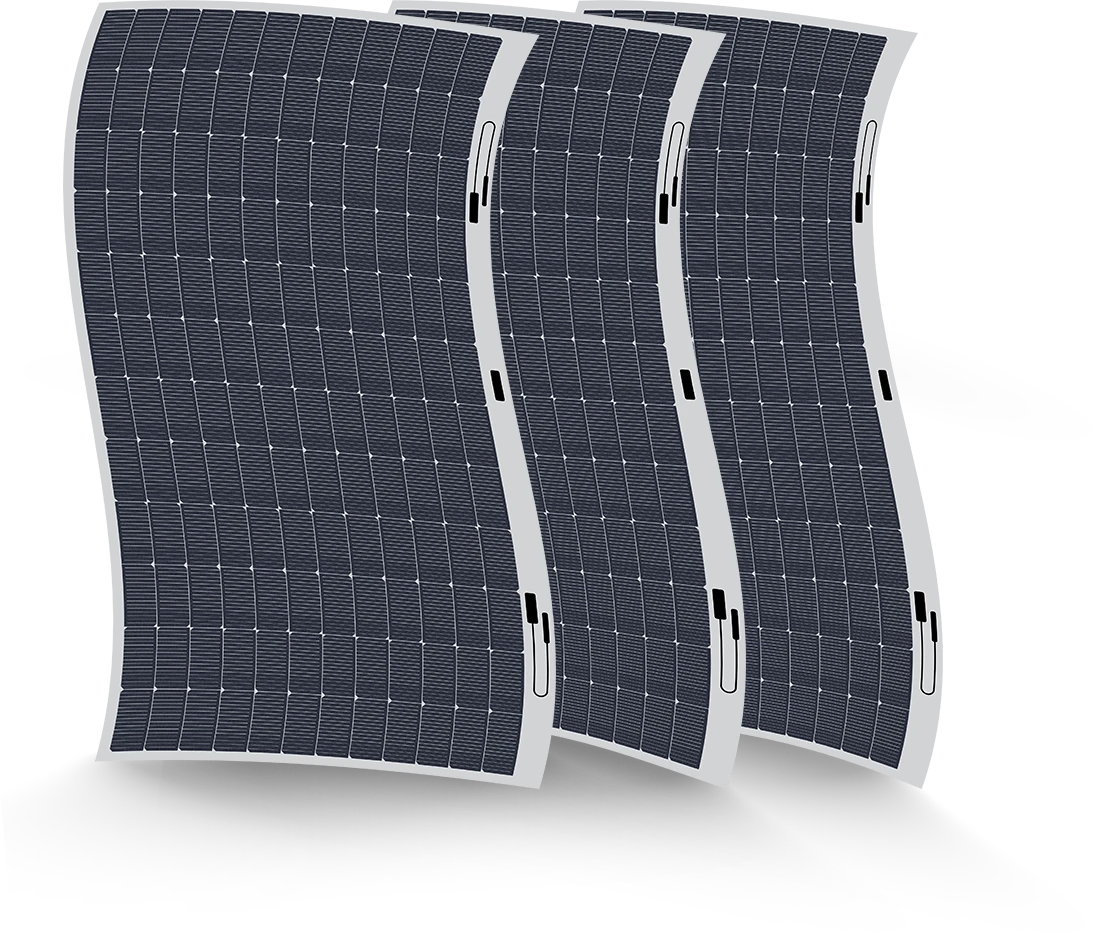

Lightweight: Lightweight photovoltaic modules can weigh as little as 2.9 kg/㎡, which makes them easier to carry and install, especially for buildings with limited roof load-bearing capacity.

Easy installation: Lightweight modules simplify the installation process, and installers can operate after simple training.

Aesthetics: The materials and designs used in lightweight modules make them more beautiful and will not damage the appearance of the building.

Safety: Due to their light weight, lightweight modules have low load requirements on the roof, reducing safety hazards caused by insufficient roof load-bearing capacity.

Customized design: The shape, size and color of lightweight photovoltaic modules can be adjusted to achieve customized design and production.

Economical: The transportation cost of lightweight modules is low, and due to their easy installation, they can reduce labor installation costs and construction difficulties.

Wide range of applications: Lightweight photovoltaic modules are suitable for a variety of application scenarios, including the lightweight roof market, BIPV (building integrated photovoltaics), mobile energy, robots and outdoor activities.

These advantages of lightweight photovoltaic modules have made them increasingly valued in the distributed photovoltaic market, especially in application scenarios with restrictions on roof load-bearing or special requirements for aesthetics.