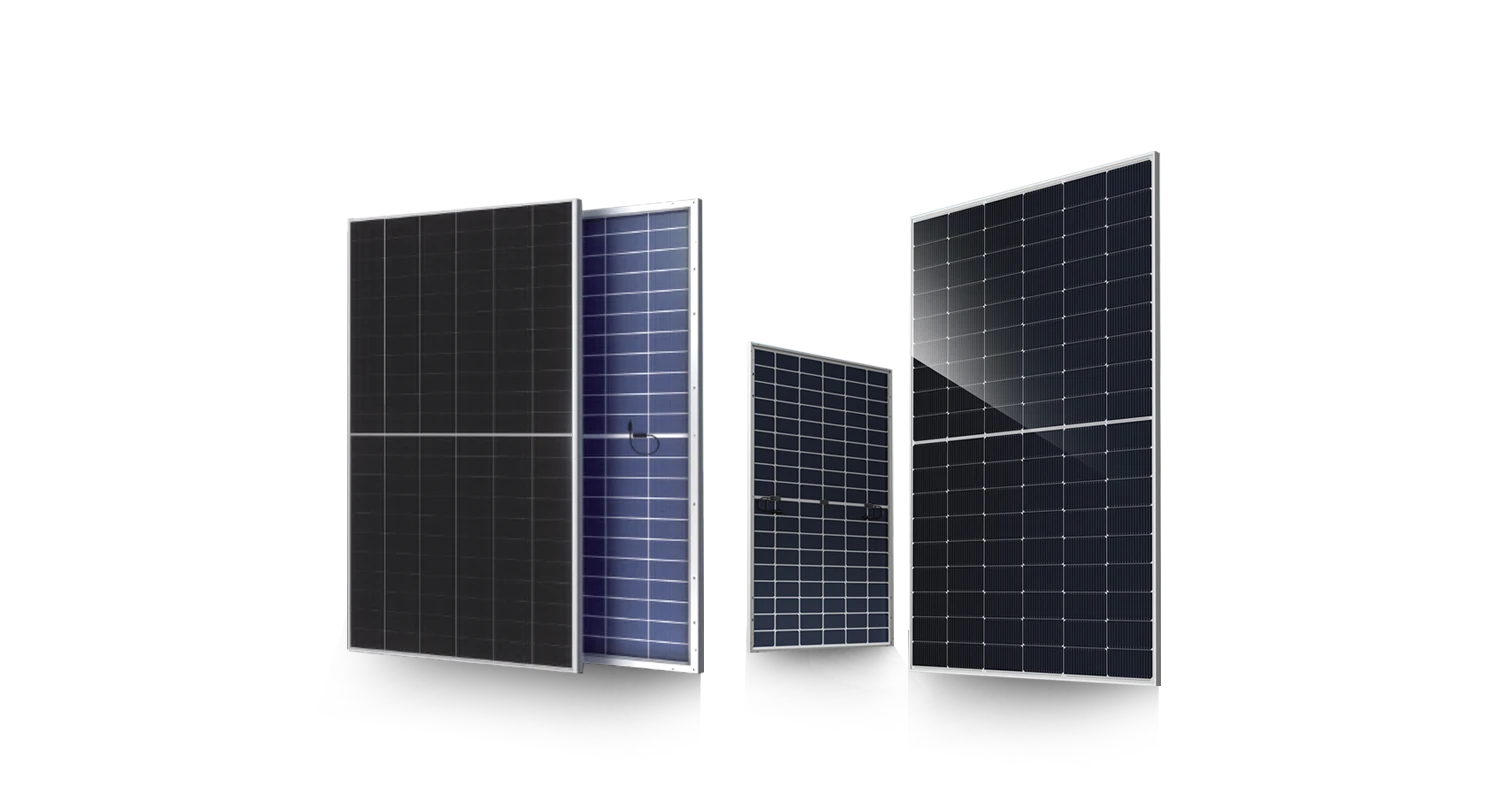

M-Size

C&I

-

-

A variety of advanced technologies are used to improve the power of components. High-conversion efficiency components are suitable for various scenarios and projects. The bifacial components have been verified globally. The high bifacial gain and high quality ensure the long-term reliability of the components.

Component Model